Considering the critical role reciprocating gas compressors & engines play in various industries, it is of high importance to assess the performance and mechanical condition of such equipment. Poor compressor or engine performance can be quickly identified and diagnosed for corrective actions to problems such as valve losses, cooler losses, or excess horsepower consumption which can indicate early warnings of potentially catastrophic running conditions.

By utilizing real-time collected performance data, actual performance outputs can be logged against simulated curves for determination of unit efficiency using our cutting-edge technology analyser used by our reliability experts to evaluate reciprocating compressors and engines, as well as rotating machinery. Our performance analyser provides the tools to evaluate mechanical condition, equipment performance, and economic return.

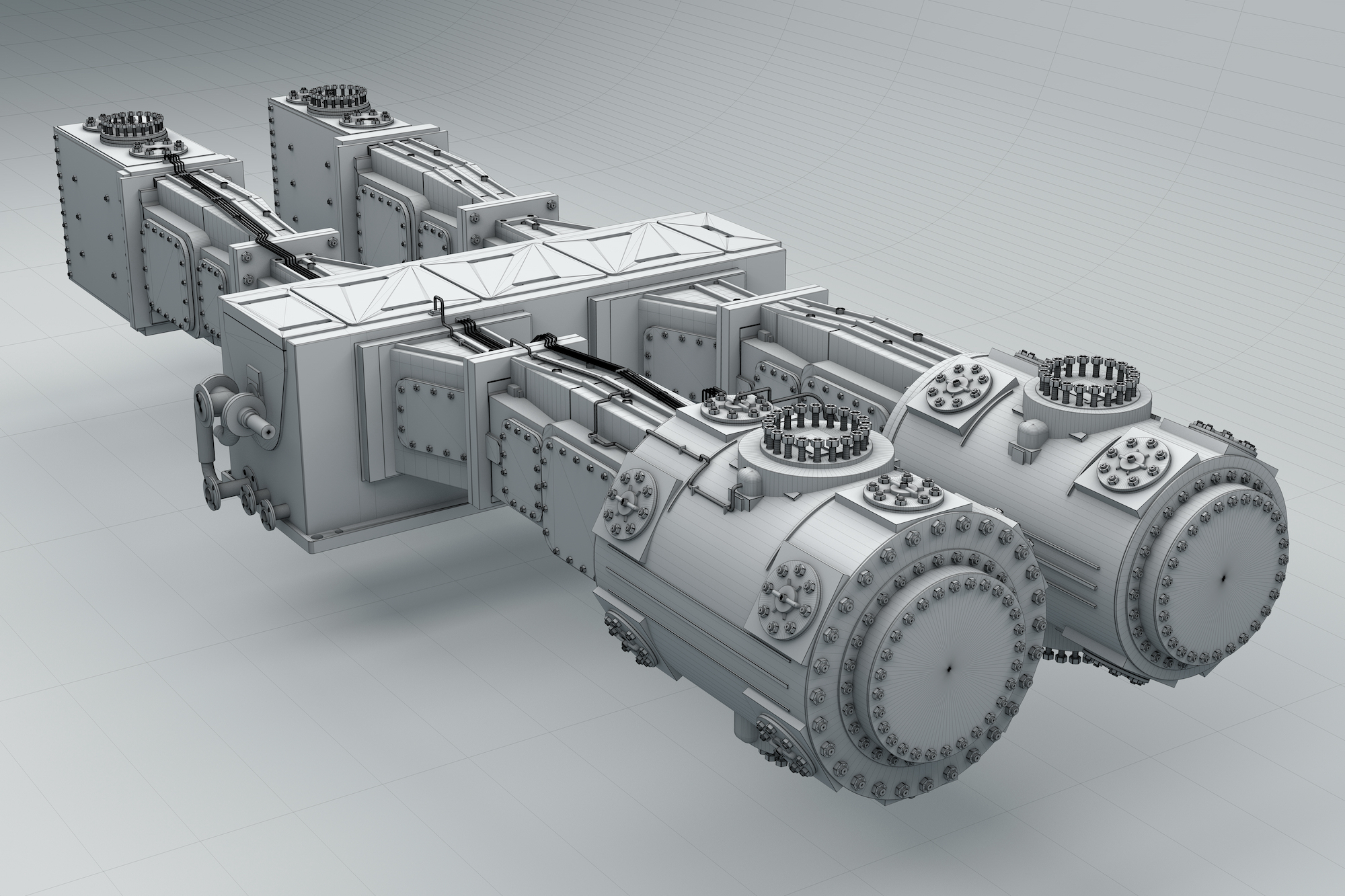

Examples of Recip. Compressor Test Results:

- Determine the mechanical condition of each compressor valve

- Identify flow restrictions or excessive pressure drops

- Find leaking rings

- Detection of loose piston on the rod

- Determine if the pockets are leaking

- Evaluate the effectiveness of the capacity control and unloader devices

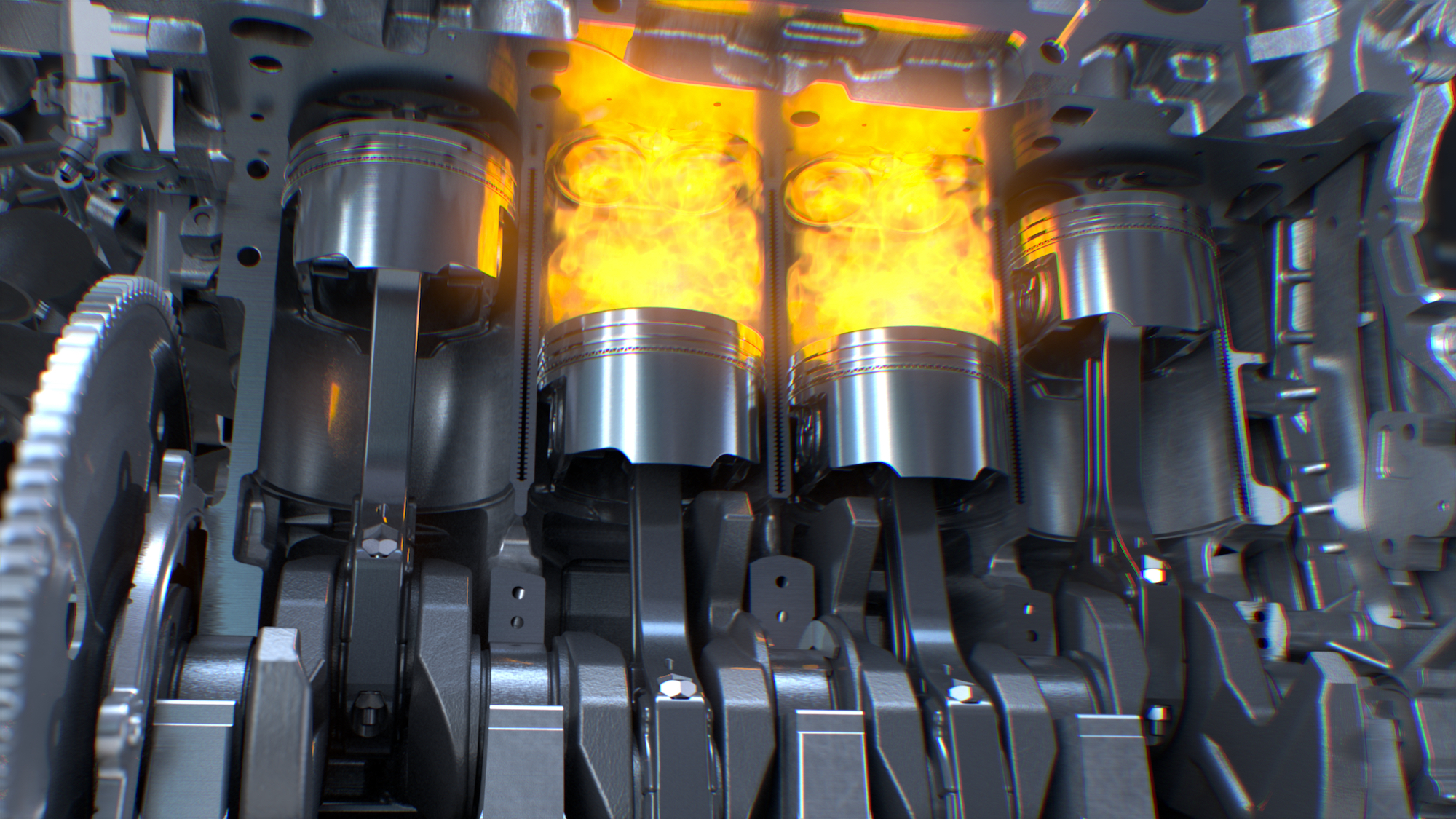

Examples of Recip. Engine Test Results:

- Determine the mechanical condition of the intake and exhaust valves

- Determine the condition of the rings and cylinder surfaces

- Determine mechanical condition of the fuel valve

- Check the timing for all valve and port related events

- Determine if the exhaust and intake ports are restricted

- Determine if there is any piston slap indicated

- Determine if there are any external leaks