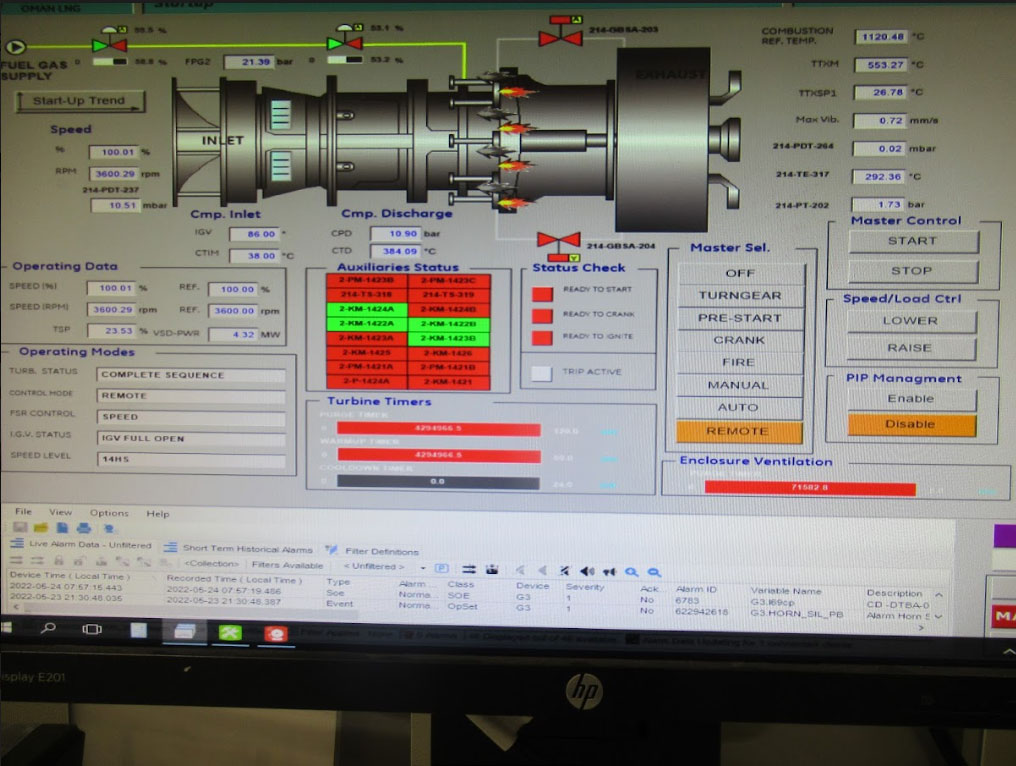

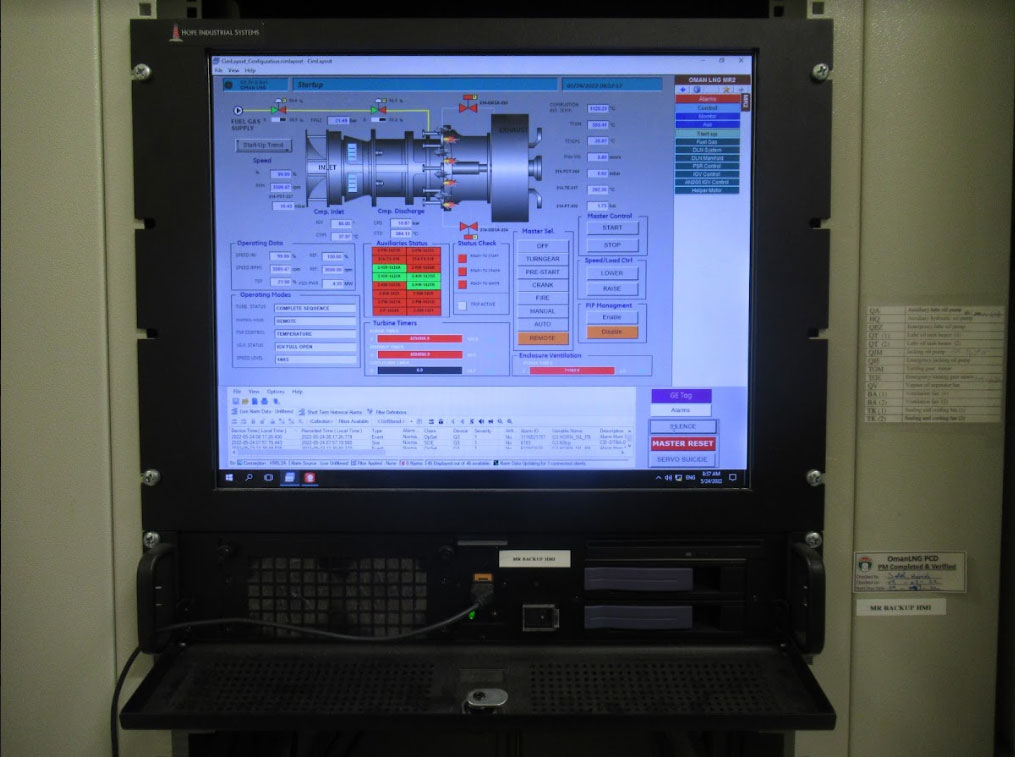

The 5-day operations and Maintenance course is designed for plant personnel involved in the daily operation and maintenance of Mark V control system and HMI. The course will enable operators and technicians to configure HMI displays and confidently, manipulate HMI software tools as well as diagnose problems in Gas Turbine SPEEDTRONIC Control Systems. The course is designed to provide a solid background in turbine governing systems. Participants increase their skills in HMI features, configuration and troubleshooting.

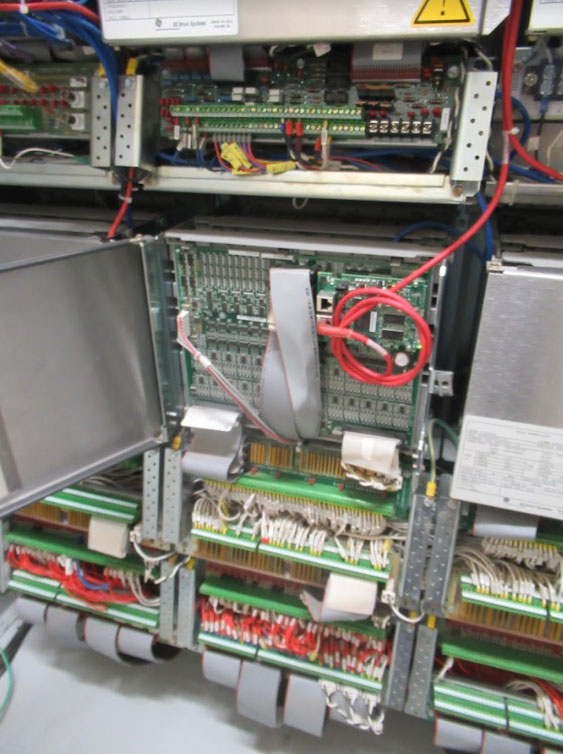

The use of a Gas Turbine simulator for the Mark V will allow students to view various operational problems and introduce the concepts of configuration, troubleshooting and fault finding.

This course provides participants with practical hands-on training in operation and Maintenance of gas turbine power plants under normal and abnormal conditions. Participants learn safe and efficient plant operation methods, plant start-up, normal operation, plant shutdown, and dealing with typical problems that occur in gas turbine power plants. The training is conducted using advanced real-time simulators that simulate typical plant problems in a realistic environment for the participants to understand, analyse, troubleshoot and respond to the problems. Participants are required to deal with associated alarms, analyse and discuss the cause and the effects of the problem scenario and to take corrective actions to restore the plant to normal conditions.

The course is 5-Day in duration using the respective simulation for Mark V. A fully concise training manual will be provided will be provided for each delegate

- Get familiar with the types of GE Gas Turbines and their applications.

- Understand and read Gas Turbine schematics and identify instrumentation devices/uses.

- Acquire knowledge of the various GE Gas Turbine Systems and explain operating requirements for Lube Oil, Hydraulic Oil and Fuel Systems.

- Be able to explain start-up, synchronising and loading procedures.

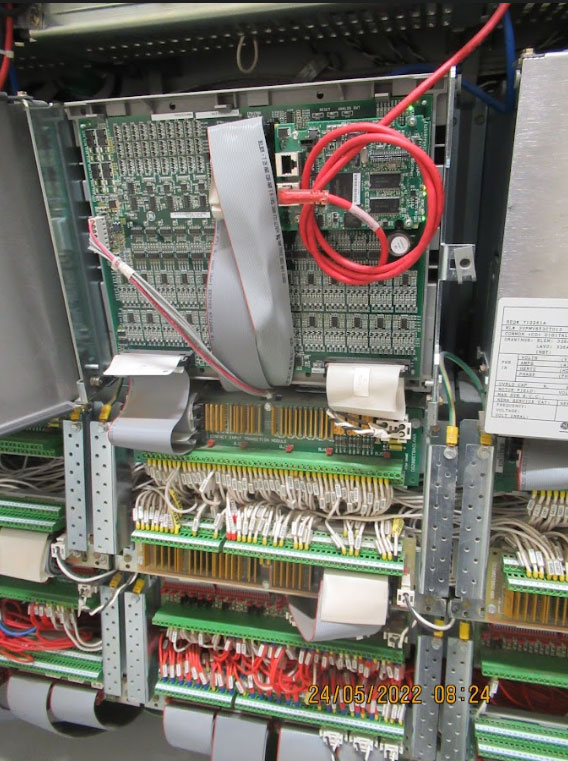

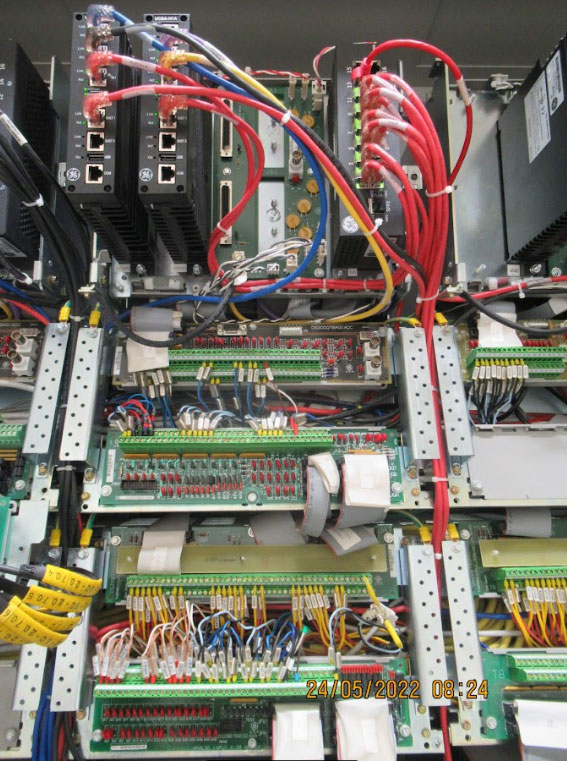

- Be able to troubleshoot, fault finding and configure sequencing.

- Be able to configure operating displays and Trip Historical display.

- Be able to use the software tools that are used to troubleshoot alarms,

- Edit the sequencing, configure the Inputs and outputs (both hardwired and networked)

- Be able to calibrate Servo-Actuated Valve, LVDT’s and other devices.

- Appreciate the principles of emissions control and the various methods of achieving this.